An established paint manufacturer needed to improve the quality of their wash water prior to discharging to the sewer system.

Contaminated wastewater is generated each time a vat or tank is washed out – usually when changing product blending. This can generate between 100 litres to 500 litres per day.

Tougher discharge limits to sewer, increasing trade waste charges and high disposal costs (pump outs) all led to a decision to treat the wastewater on-site.

Equipment Supplied:

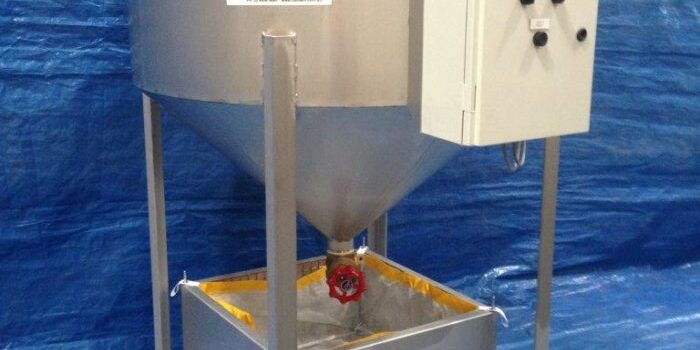

The ideal solution came in the form of a BUSTA, designed and built by Baldwin Industrial Systems Pty Ltd, Cardiff, NSW.

The BUSTA is an economical, manual Stainless treatment unit complete with mixer and timer, catch tray and filter bag. The dry sludge produced by the addition and mixing of RM-10 clay-based chemicals, can be disposed of directly into the rubbish skip and the clean water can be discharged direct to sewer.

Performance:

The BUSTA can easily treat three to four batches of 350 litres per day.

Various “semi-automatic” additions are possible depending on specific site requirements.

The BUSTA – RM-10 combination can remove (and fully encapsulate) suspended solids, oils and greases, heavy metals, surfactants, etc.

The clean, treated water may also be recycled, if justified.

Typical Results:

| Contaminant | Raw Wastewater | After Treatment |

| pH Range | 8-9 | 7-8 |

| Suspended Solids | 10,000 | <500 |

Results:

There are numerous BUSTA units that have been successfully operating in the paint industry for over fifteen years, all of which provide the owners with considerable savings in time and disposal costs.