Oil skimmers are devices which assist in the removal of oil and other contaminants from water. The skimmer uses a mechanism to attract the oil and pull it towards the skimmer’s surface. Once the oil comes into contact with the skimmer, it sticks to a belt or tube and is lifted away from the water surface, or is removed with the surface layer of the water by a floating oil skimmer.

The main types of oil skimmers

Belt Oil Skimmers

One of the most widely used types of oil skimmers is the belt oil skimmer. These skimmers employ a continuous loop of corrosion-resistant steel or synthetic medium, which is submerged into the fluid to be skimmed. As the belt passes through the water surface, the floating oil adheres to the medium, effectively separating it from the water. The collected oil is then removed from the medium using wiper blades or pinch rollers. Belt oil skimmers are simple yet highly effective and find applications in a wide range of industries.

Tube Oil Skimmers

Tube oil skimmers utilise a floating oleophilic hose that extends across the liquid’s surface and is then drawn back through the skimmer’s drive unit. During this process, oil adheres to the tube’s surface and is subsequently removed by scrapers or wipers. Tube skimmers are particularly useful in applications with relatively thick layers of oil, making them suitable for various industrial settings.

Floating WEIR Oil Skimmers

Floating oil skimmers come in various forms, all featuring a floating intake mechanism. These skimmers are most effective when dealing with thicker layers of oil, typically 6mm or more. However, they can be less efficient when dealing with thin layers or emulsified oils. Some floating skimmers can even inadvertently emulsify oil due to churning during the suction process. To enhance their effectiveness, they often require coalescing or decanting units, such as coalescing plate separators.

When would you use an oil skimmer?

There are a number of instances in which you would use an oil skimmer such as:

General Oil Spills

Oil spills can occur in various settings, from industrial facilities to transportation accidents. In these emergency situations, immediate action is crucial to minimise the damage caused by the spilled oil. Oil skimmers are adept at swiftly containing and recovering the spilled oil from water surfaces. Their ability to remove oil efficiently ensures a prompt response, preventing further spread and preserving the integrity of the affected area.

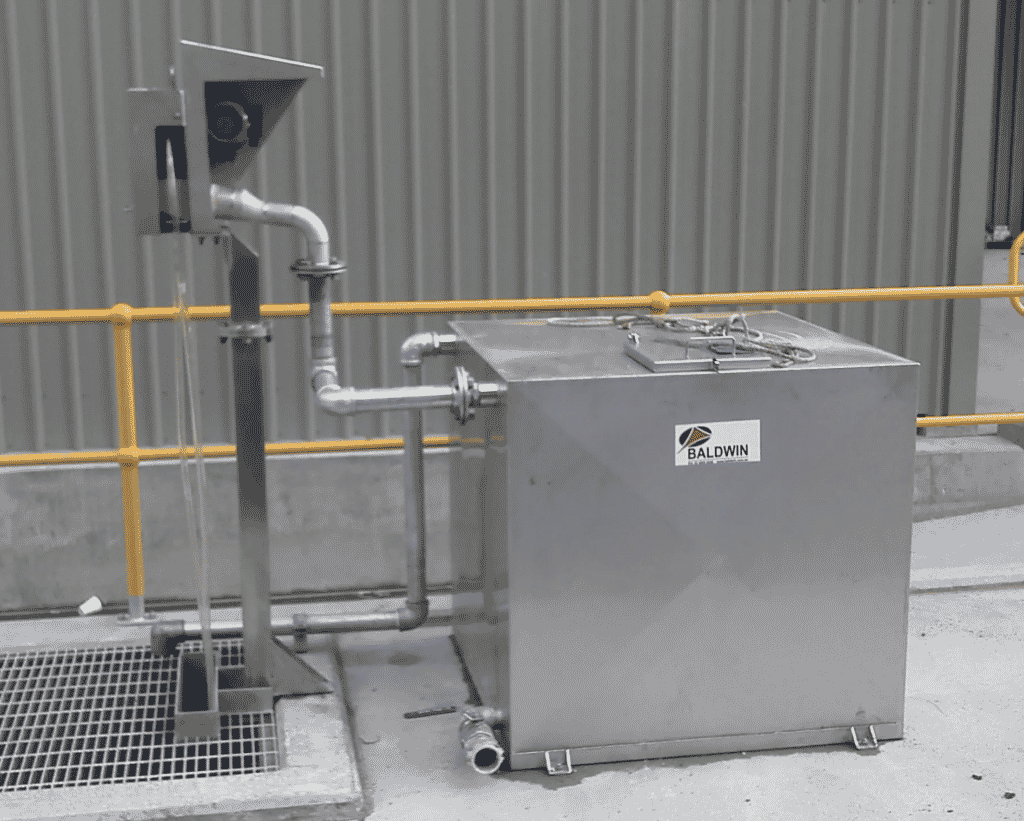

Wash bay

Washing dirty and oily equipment in a mining or industrial application can generate a significant quantity of free oil in the wash water. An oil skimmer is an effective method to remove a majority of the free oil and thereby reduce the pressure on downstream wastewater treatment equipment such as coalescing plate oil separators.

Wastewater Treatment

One of the primary uses of oil skimmers is in wastewater treatment systems. As industries discharge their wastewater into treatment plants, it often contains oil and grease floating on the surface. Oil skimmers are employed in these facilities to remove the oils before further treatment processes. By removing the oil from the surface, the skimmers help prevent clogging of pipes and filters, and enhance the overall efficiency of the treatment process.

Food Processing Equipment

The food processing industry extensively utilises oil skimmers for the effective removal of oils and greases from water. During the food production process, oils and fats are often released into the water. These contaminants need to be removed to maintain the quality and safety of the processed food. Oil skimmers play a vital role in ensuring the removal of these substances, preventing contamination and ensuring compliance with hygiene standards.

Contaminated Ponds and Lakes

Oil spills and leaks can have a devastating impact on the environment, especially when it comes to ponds and lakes. In the case of accidental spills or leaks, oil skimmers are deployed to rapidly and efficiently recover the floating oils. By removing the oil from the water surface, these skimmers help mitigate the environmental damage, protect aquatic life, and restore the affected ecosystems.

What’s the difference Between a Skimmer and Scraper?

While skimmers and scrapers both play roles in oil removal, they serve different purposes. A skimmer is specifically designed to remove floating oil from the surface of water, making it effective for large-scale oil spills or contaminated water bodies. On the other hand, a scraper is primarily used for the removal of settled or thick layers of oil and sludge from the bottom of tanks or pits. The scraper’s function complements that of the skimmer, ensuring comprehensive oil removal from various parts of the water body.

What’s the difference between a skimmer and an absorbent?

Skimmers are specifically designed for managing oil on liquid surfaces, such as water bodies or industrial tanks. They are not suitable for addressing oil spills or leaks on solid surfaces, like on a factory floor. In contrast, absorbents can be applied directly to solid surfaces to soak up and contain spilled oil, making them a valuable option for immediate response in these situations.

Skimmers are generally considered permanent solutions, as they can operate continuously, removing oil from water without the need for frequent replacement or replenishment. In contrast, absorbents are considered consumables. Once they have absorbed a certain amount of oil, they become saturated and need replacement or disposal.

If you require advice on oil skimmers, don’t hesitate to contact the team at Baldwin to discuss the most suitable product for your situation.